PCB Assembly Expert

GOPCBA is more than just a leading PCB Fabrication manufacturer, but also a one-stop shop for all your printed circuit board Assembly requirements, we provide PCB design & layout, PCB fabrication and PCB Assembly services(also called printed circuit assembly, circuit board assembly, printed board assembly, printed circuit board assembly and smd assembly ) and turnkey services all under one roof.

- Home

- PCB Assembly

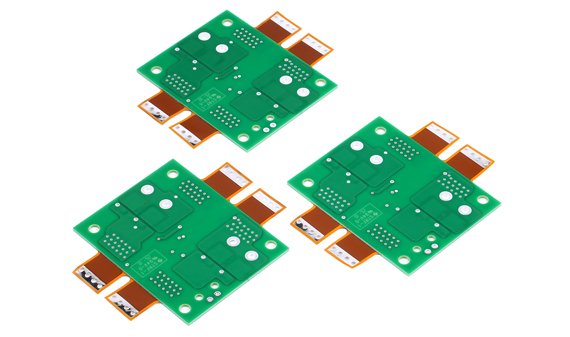

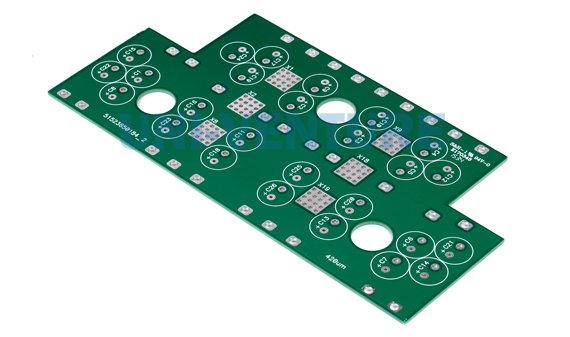

PCB and PCBA Product Showcase

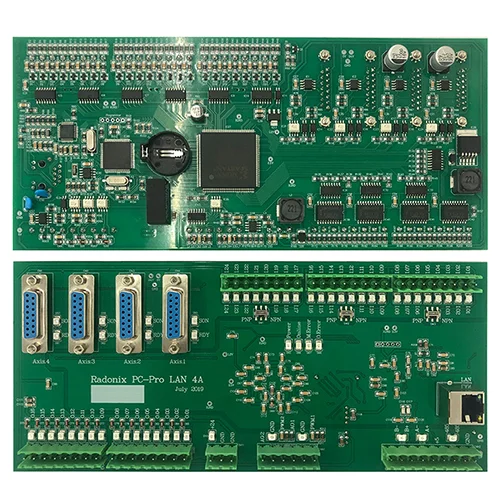

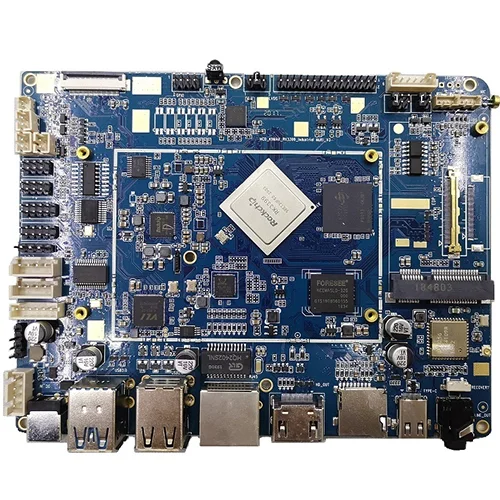

SMT PCB Assembly

Medical Ventilator PCB Assembly

Through-Hole PCB Assembly

High Volume PCB Assembly

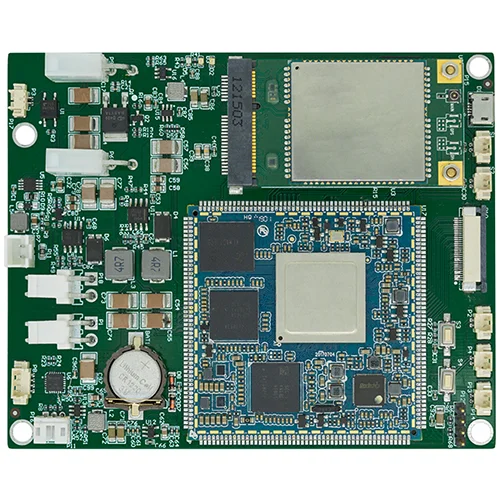

Prototype PCB Assembly

Turnkey PCB Assembly

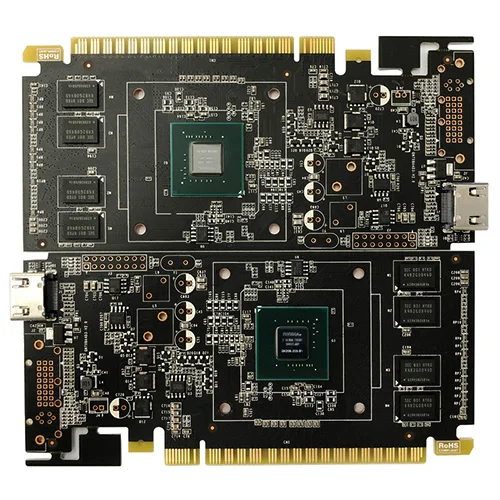

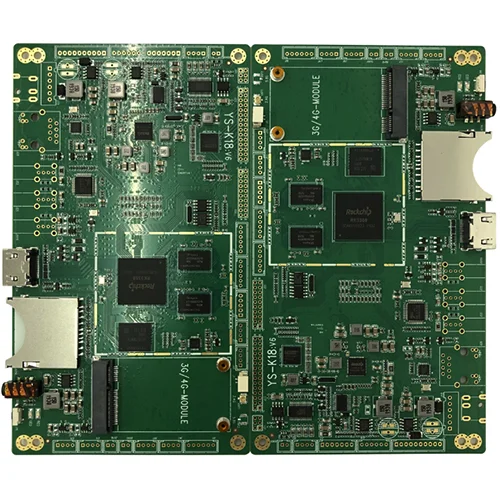

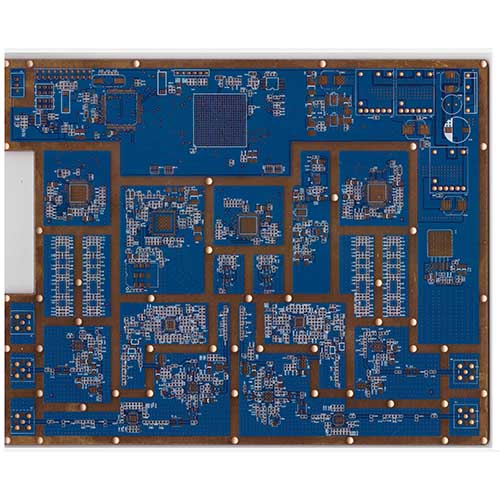

10-Layer Hybrid PCB

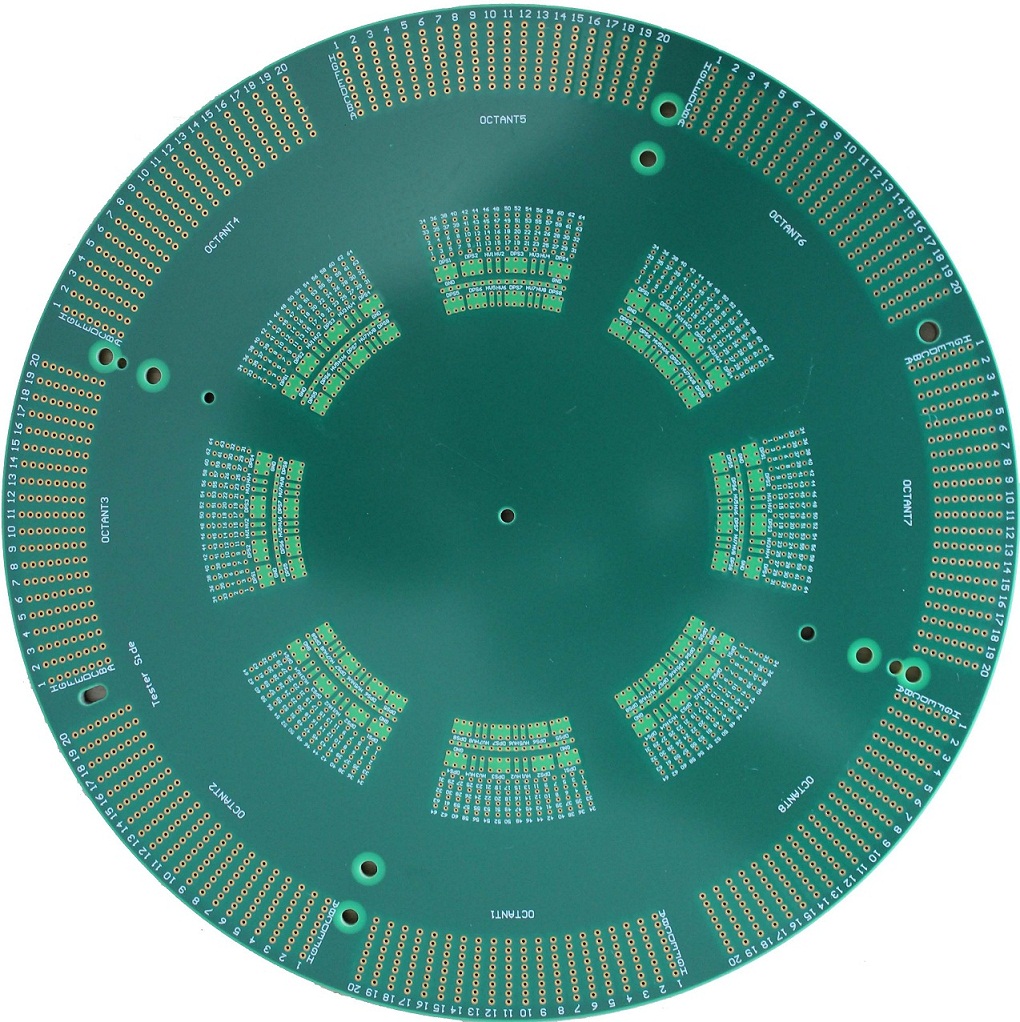

12-Layer IC Test Board

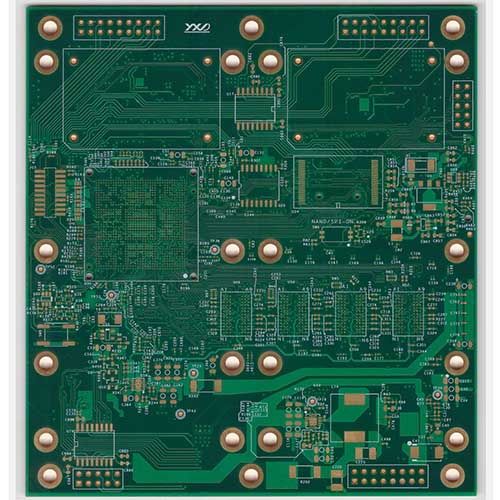

10-Layer Military Embedded Core Motherboard

GOPCBA PCB Assembly

Your Best PCB Assembly Expert in China

You can provide all the electronic components including the bare printed circuit boards(kitted), we assemble your boards using our precise equipment;

You can also provide partial components and we purchase the reminder components and we assemble your boards(partial kitted).

Or we can also provide you turn-key assembly services by we make bare printed circuit boards and purchase all the components and do the assembly.

At GOPCBA we can answer any PCB assembly questions that you may have, pls feel free to contact us anytime for your custom PCB assembly projects.

- PCB Assembly from Rigid, Flex to Rigid Flex board with leaded & lead-free solder

- No minimum order requirement, order start from 1 pcs

- 7/24 Live sales & tech support

- Full Range Of Reliable Suppliers For Components

- 8-48 hours delivery time when components are ready

GOPCBA: Your Best PCB Assembly Manufacturer in China

We can work with BGA of 0.35mm pitch with X-ray testing, Passive Components minimum 03015 package, Fine Pitch Components minimum 0.38mm pitch.

Our Test types include visual inspection, X-ray inspection, AOI testing, In-Circuit test and functional test (customer provide functional test instructions).

GOPCBA has relationships with all top distributors such as Digi-key, Mouser and Element 14. Our engineers will give you expertise in DFM (Design for Manufacturing) checking for your every order, we verify all details of your files including BOM and Gerber files to allow you to correct your PCB design before we build it, saving significant time and cost and avoiding unnecessary repeats of the prototyping assembly process.

No matter you are an electrical engineer, a product designer, a system integrator or a maker looking for PCB fabrication and assembly, or PCB manufacturing and assembly, or electronic assembly services(electronic PCB assembly) ,or a low cost PCB assembly house, GOPCBA PCB assembly team will be your perfect PCB assembly house in China.

The difference between a PCBA and a PCB

A PCB refers to a blank circuit board, while a PCBA refers to a panel that contains all the electronic components needed for proper operation.A PCB is not yet functional because it lacks the necessary elements, but a PCBA is fully functional.

The manufacturer creates the PCBA on top of the existing PCB. therefore, PCB and PCBA are two different parts of the same process.

How do PCBAs and PCBs relate to each other?

Cost: The process of generating a PCBA is more complex ,so it more expensive due to the different components and processes involved in PCB assembly

Packaging: PCBs are usually vacuum packed, whereas PCBAs require compartmentalised or anti-static packaging.

Download Your FREE

PCB & Assembly Catalog

Capabilities of PCB Assembly

| Item # | Item Name | PCB Assembly Capabilities | |

| 1 | Lead Time | Our service ranges from 8- 48 Hours for prototype and small GOPCBA PCB assembly projects. Since each project complexity is different, our turn-time starts from the time that all the components, PCB files (Gerber files/other PCB files, etc.,), Centroid (Pick & Place PNP file, or XY Data or files in other formats), BOM, and all the other necessary data or documents/images/photos are ready, then we start our assembly work. | |

| 2 | Parts Source | kitted(Consigned) | Our Kitted PCB Assembly requires you supplying all the components and ship to us. |

| Partial Kitted | Our Partial Kitted PCB Assembly service means you offer the main components, and we source the best components for you and returned you assembled boards. We will ask for your approval on every detail of the components concerning price, quality, and availability. | ||

| Turn-key | Our Turn-key PCBA service is based on our worldwide network of components sourcing .we source from reliable suppliers such as Digikey/Mouser/TME/Element 14 and also local authorized distributors. We will always ask for your approval before making any decisions on equivalent components and. | ||

| 3 | Assembly Options | We offer Surface Mount (SMT) Assembly, Thru-Hole (THT) Assembly, hybrid of both( Mixed Assembly) , BGA & QFN Assembly and Kit Assembly, with single or double-sided placement, Fine Pitch Component Insertion. Automatic (spray) and Manual(spray & brush) comformal coating both available upon request. | |

| 4 | Types of Solder | We offer both leaded and lead-free (RoHS Compliant) PCB assembly services for our customers. | |

| 5 | Stencils | We use laser cut stainless steel stencils to ensure high reliability for fine pitch and Ball Grid Arrays (BGA) components. | |

| 6 | Minimum Order | Our minimum order qty is 1 pcs. Especially focused on prototype (1-10pcs), small batch(10-100pcs) assembly and low volume PCB(100-500pcs) assembly | |

| 7 | Component Size | Passive Component: we can handle passive components as small as 03015, 01005, 0201,0402. | |

| BGA: We have the ability to handle Ball Grid Arrays (BGA) of 0.35mm pitch with X-ray testing. | |||

| Fine Pitch Components as small as 0.38mm fine pitch parts. | |||

| 8 | Component Package | We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. | |

| 9 | Board Dimension | Min Board Size: L50mm x W50mm (Boards smaller than this size need to be panelized) | |

| Max Board Size: L 774mm x W710mm | |||

| 10 | Board Shape | We can assemble boards in Rectangular, Circular, and any Odd Shapes. For PCB shapes other than a rectangle, pls penalize the bare PCBs (printed circuit boards) in an array, and add break-away fields at the two longer paralleled edges of the panelized boards, in this way boards can be assembled by the machine, our engineers can help you with PCB panelization if needed. | |

| 11 | Board Type | We can assemble Rigid Boards ( FR4, CAM..etc), Metal Core (Aluminum,Copper) Boards, Flex Board( Flex PCB),Rigid-Flex Board(Rigid – Flex PCB) | |

| 12 | IC Programming | DIP, SDIP QSOP, SSOP TSSOP, PLCC QFN, MLP BGA, CSP SOT SOP, MSOP TSOP QFP, MLF DFN | |

| 13 | Inspections | Visual inspection: general quality check. | |

| X-ray Inspection: checks for BGAs, QFN, and bare circuit boards. | |||

| AOI Testing: checks for solder paste, 0201 components, missing components, and polarity. | |||

| ICT (In-Circuit Test) | |||

| 14 | Functional Testing | Functional testers Test software Design For Assembly Functional Testing(FCT) | |

| Avoid assembly issues Correct component failures Troubleshooting program | |||

| The functional test will follow your test procedures | |||

Why choose GOPCBA as your PCB assembly factory?

High Efficiency, Low Cost Flexible GOPCBA Assembly Alternatives:low volume, high volume. Prototypes Multiple PCB Assembly Services:SMT, THT, Mixed Assembly, Package on Package (POP), Rigid PCBs, Flex PCBs, etc

Parts Sourcing:with authorized electronic components manufacturers and distributors Comprehensive Quality Assurance: inspection to AOI and X-ray inspection before assembly Professional Engineering Team:Engineers are professionally trained

PCB Assembly: The Ultimate Guide

Honestly, PCB assembly is one of the most challenging aspect in the electronics manufacturing process.

Whether in the smartphone, digital watches, medical equipment or industrial machines, you must do it right.

The best part?

Today’s guide covers all the critical aspects of printed circuit board assembly process.

It focuses on the following:

- PCB Assembly Definition

- PCB Assembly Applications.

- PCB Design Basics

- PCB step by step Assembly Process

- PCB Assembly Process flow

- PCB Assembly Techniques – Automated and Manual

- PCB Assembly Capabilities

- Hiring PCB Assembly Company

Now we dive into the detailed segments…

- What is PCB Assembly?

- PCB Assembly Applications

- PCB Design Basics – Learn the Basic Steps in PCB Design

- Types of PCB Designs

- Steps In PCB Assembly Process

- Printed Circuit Board Assembly Process Flow

- Printed Circuit Board Assembly Techniques

- PCB Assembly Capability

- SMT Assembly of Printed Circuit Boards

- How to Hire Professional PCB Assembly Company

- Conclusion

Chapter 1: What is PCB Assembly?

Have you ever noticed that the boards had got several components firmly attached to them? What do you think they are?

Many would think they serve for decorations. Absolutely no.

PCB is not capable of independently functioning without those components.

Meaning every single one of them is vital and significant to the functioning of the board.

Technically speaking, detaching any single component would impair the operation of the PCB.

All these elements get embedded through a distinct manufacturing process.

Thus, it is this procedure that we refer to as the PCB assembly abbreviated PCBA process.

If you have a close look at the board, then you should see various copper lines.

These are the traces.

They are very tiny yet serve an essential purpose.

Traces link all the components and connectors of the PCB amongst themselves electrically.

They do this by supplying signals throughout these constituents thereby achieving the operation of the board.

Essentially, PCBs serve from simple to complex functions.

Unlike other electronic devices, size doesn’t matter here, in fact, some are tiny and thin, yet they continue to function optimally and run complicated tasks.

So what are the exact areas applications of PCBs?

Chapter 2: PCB Assembly Applications

To date, the PCBs are in almost all sectors of the economy and industries. It also continues to grow into other unexplored segments.

Now that virtually all electronics have PCBs, it’s easier to pinpoint their uses.

With every development in advancement in technology, PCBs configurations as well improve and become better suited to sustain and tolerate even some of the hostile environment.

The flexibility and configurations of these circuits enable the PCBs to work in various segments and applications.

Remember, at the core of any electronic device is a PCB.

The modern technology significantly utilizes these circuits.

Now, let’s explore some of the typical applications where we got the PCBs incorporated:

1.Industrial applications

The boards run seemingly high-powered machines primarily in the manufacturing or processing factories.

In these areas, the PCBs are fabricated to adapt to and sustain the harsh conditions in which they are getting exposed.

Such PCB assembly can withstand:

- Tremendous multitude vibrations

- Corrosive chemicals

- Extreme mechanical stress

- Fluctuating temperature, etc.

Due to such ever-increasing challenging conditions in the industrial setups, the PCBs technological advancement has been over time propelled to solve the problem.

For that reason very thick copper printed circuit board fits in situations where the average or standard PCBs aren’t favorites.

Note that thick copper PCBs serve a similar purpose to the ordinary ones.

However, the significant difference is that the former one is capable of sustaining a high amount of current output demand together with the battery charge.

PCBs are in the: Electric drills, presses, hydraulics, generators especially in the manufacturing and processing industries.

Measuring instruments including Pressure pumps, thermometers, weighing scales, etc.

Power generating equipment such as DC – AC converters, power generators