High Volume PCB Assembly

High Volume PCB Assembly

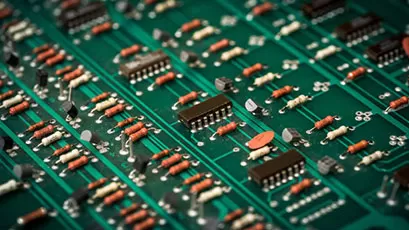

We also provide custom PCB assemblies for high-end modern electronic manufacturing companies. Our end-to-end high volume PCB assembly services are ubiquitous and have been serving various industries and businesses. We have tons of costumes across the globe making product requests to deliver high volume printed circuit boards every month recording envious customer retention.

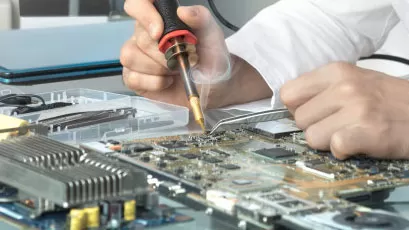

From prototype to production, our engineers support you solidly and pay apt attention to delivering top-notch PCB assembly services. Quality still remains the cornerstone of all our services. We are also an ISO certified printed circuit board assembly company since 1999 with IPC trained personnel who also conduct triple process inspections for high volume PCB assembly requirements. Our workmanship is of the highest grade and you can be assured of the durability, quality, and performance of your circuit board assemblies.

Get the exceptional value through our

Large Volume PCB Assembly Service

Minimal Failures – We are committed to procuring the components only from the certified and authorized vendors to maintain the product quality, prevent component failures, and ensure component traceability. We also follow a variety of extensive testing methods.

Specialist Team – Even for the high volume PCB assembly orders, we maintain the same dedicated departments and teams for handling other allied business operations. We maintain the entire workflow – fabrication, procurement & supply chain, tooling, testing, automation, quality assurance, downtime maintenance, etc.

Uncompromised Quality – We offer unmatched capabilities for providing uniform high volume printed circuit boards. All of these PCBs would have the same quality standards as we follow a rigorous testing and inspection process. We do not sacrifice quality for any other thing.

Accelerate the production with

High Volume PCB Assembly Services

Layout and PCB Fabrication

Components Sourcing

Large/High Volume PCB Assembly

Plastic Injection

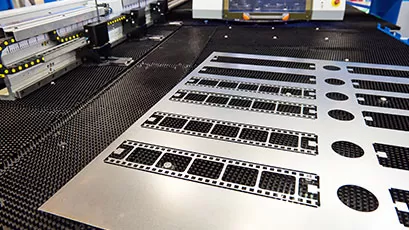

Metal Stamping

Turnkey Assembly & Final Testing

Capabilities in High Volume PCB Assembly

| Supported Capabilities | |

|---|---|

| Assembly Types | Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, complex circuit on one side, BGA on both sides |

| PCB Thickness | 0.5mm~4.5mm |

| Copper Thickness | 0.5 oz to 5.0 oz |

| Minimum Line Width | 3 mil |

| Minimum Line Spacing | 3 mil |

| PCB Size | 50 mm×50 mm ~450 mm×406 mm |

| Stencils | Laser-cut stainless-steel stencils |

| Components | Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch, Leadless chip carriers/ BGA, VFBGA, FPGA & DFN, Connectors and terminals |

| Inspection | X-ray analysis, AOI, and Microscope to 20X |

| Solder Type | Leaded and Lead-free/RoHS compliant |

| Board Shape | Rectangular, Circular, Slots and cut-outs, and any Odd Shapes as per requirements |

| Min. Diameter / Space of BGA | 0.2mm / 0.35mm |

| Board Type | Flex, Rigid, Rigid-flex |

| Minimum Order | No Minimum Order |

| Component Size | Smallest Components, BGA, Micro BGA, and Fine Pitch Parts Assembly |

| Types of Finishing | Carbon, Selective Gold Plating, SMBOC(HASL), OSP, Hard and Soft Gold Immersion Gold, Immersion Silver, Immersion Tin |

| Supported File Formats | BOM: .xls, .csv, .xlsx Gerber (RS-274X) Centroid (XY, Pick-n-Place) |

| Testing | Flying Probe Test / Fixture Test, Impedance Test, Solderability Test, Thermal Shock Test, Hole Resistance Test, and Micro Metallographic Section Analysis, etc. |

High Volume PCB Testing Capabilities

Mer-Mar Electronics has experienced and skilled experts who strive to ensure boards irrespective of their size and volume, have been rigorously tested for quality at every stage of the manufacturing. To maximize quality assurance of large batch PCB assemblies, we perform extensive testing and inspections on all the PCBs irrespective of the volume. We follow a strict quality control process till the boards are shipped out.

We have great proficiency in high volume PCBs and create matchless PCB designs with zero to the minimal margin of error. We make sure all these boards work uniformly. To maximize the quality of these large batch products, we perform extensive testing of all the products. Our expert engineering team leaves no room for improvement after finalizing the product.

We are an ISO 9001:2015 certified company and for the pursuit of the highest PCB quality, we procure parts from authorized vendors. We focus on the components sourcing process as it is the key to maintain production quality. We ensure full traceability and also try to prevent any component failure issues.

Below are the tests we conduct –

- A design for manufacturability (DFM) – To make sure your design is suitable for high volume PCB manufacturing

- DFA checks – For detecting issues that negatively impact the PCB fabrication process

- AOI and AXI tests – Before packaging and shipping

- Custom function tests – As needed

- Electrical Testing – For confirming the PCB functionality to its original design

- Flying Probe Testing – To test electrical performance

- Functional Testing – To make sure everything is working as per the specific requirements

- In-Circuit Testing

- X-ray Testing

- Solder Paste Inspection

High Volume PCB Assembly Technologies

We follow three methods to construct high volume PCB assemblies

- Surface Mount Assembly – Through the SMT technique, we achieve miniaturization capabilities and build PCBs with high mechanical strength. For over 40 years, we have been providing SMT PCB assembly services and are totally equipped for ensuring optimal performance even in the shakiest or challenging conditions. Our competitive advantage is based on state-of-the-art technology and a competent team of engineers assures you of quick turnaround times, highest quality standards, and take the entire hassle away from you.

- Through-hole Technology – We provide end-to-end through-hole PCB assembly services right from prototype to production. We are fully equipped and competent to handle double wave flow solder services, RoHS soldering, manual & automated component placement, and testing of your boards. High-end technology solutions will be delivered with international quality standards in the lowest turnaround times. We provide both manual and automated techniques and offer complete reliability, high quality PCB at optimal costs, and minimal turnaround times.

- Mixed – We render Mixed PCB assembly services by effectively going for Surface Mount Technology (SMT) as well as Through-hole technique and use them with an optimal blend of both of these.

Multifaceted Applications of High Volume PCB Assembly

We use high volume PCB Assembly services in electronic manufacturing companies for delivering consistency, uniformity, and automated manufacturing. The industrial applications for high volume PCBs are expanding constantly.

- Automotive

- Aerospace

- Computers

- Defense & Defense

- Electronics

- Medical

- Modern Electronics

- Telecommunications

Certifications

- IPC certified

- RoHS compliant

- ISO certified

- UL Standards

- ISO 14001:2015

- ISO 9001:2015

- IATF 16949:2016

This is heading text

High volume PCB Assembly refers to bulk printed circuit board assembly projects of 10,000 pieces or more, in one cycle of production with DFM and DFT. This is highly popular in high-end modern electronic manufacturing companies.

The benefits of high volume PCB Assembly are

- One-time design and prototyping services

- Faster time-to-market

- cost-efficient as you can purchase in bulk

- Consistent quality

- Production uniformity

- Shortened production cycles

Choosing a high volume PCB manufacturing company is quite a daunting task in this cut-throat competitive space. Two of the most common things one looks for in any company are quality and cost-effectiveness. Besides, you can also look into their experience, manufacturing capabilities, turnaround time, responsiveness, value for time & money, flexibility, and customization options.

Mer-Mar Electronics is a USA-based PCB fabrication and manufacturing company with over 4 decades of experience in PCB assembly services. We are an ISO-certified and ITAR-compliant company. We offer high volume circuit boards in the least turn-around time, flexible shipment plans, and at competitive prices. We follow a client-centric approach to ensure guaranteed quality satisfaction.

You can send your Gerber files and BOM to us We would provide you the quote Give your confirmation and the order We start with PCB fabrication component procurement We perform soldering and testing Finally, we go for packaging and shipping to you.

Well, we can accurately present the time based on the complexity of your board. Let us first go through your Bill of Materials (BOM) and Gerber files. See how much time it takes.

Yes, we do. After the PCB assembly, we can launch an x-ray test on your components. The additional charges will be levied after the assembly test.

We make sure you face zero issues. However, if unfortunately, you face any problems with the boards, please send high-resolution images for proper evaluation. If we get a confirmation of the root cause, we will take responsibility for your board repairs.

As part of the high volume production process, we provide components and parts procurement for optimizing the manufacturing process at zero price. Also, repeat customers may also take advantage of loyalty discounts to reduce the long-term costs of production. Depending on your requirements, we would let you know the final costs.

Yes. We do offer reliable customer support for your orders from start to finish. We will walk you through every step of the process and our PCB experts will also be available all the time.