Automotive PCBs

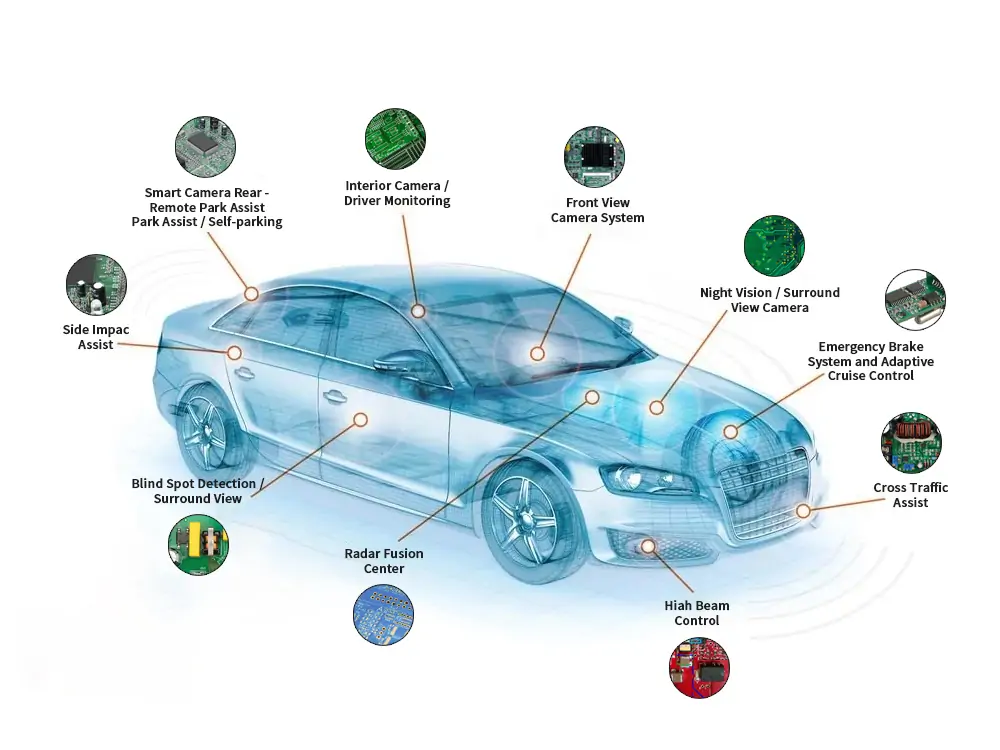

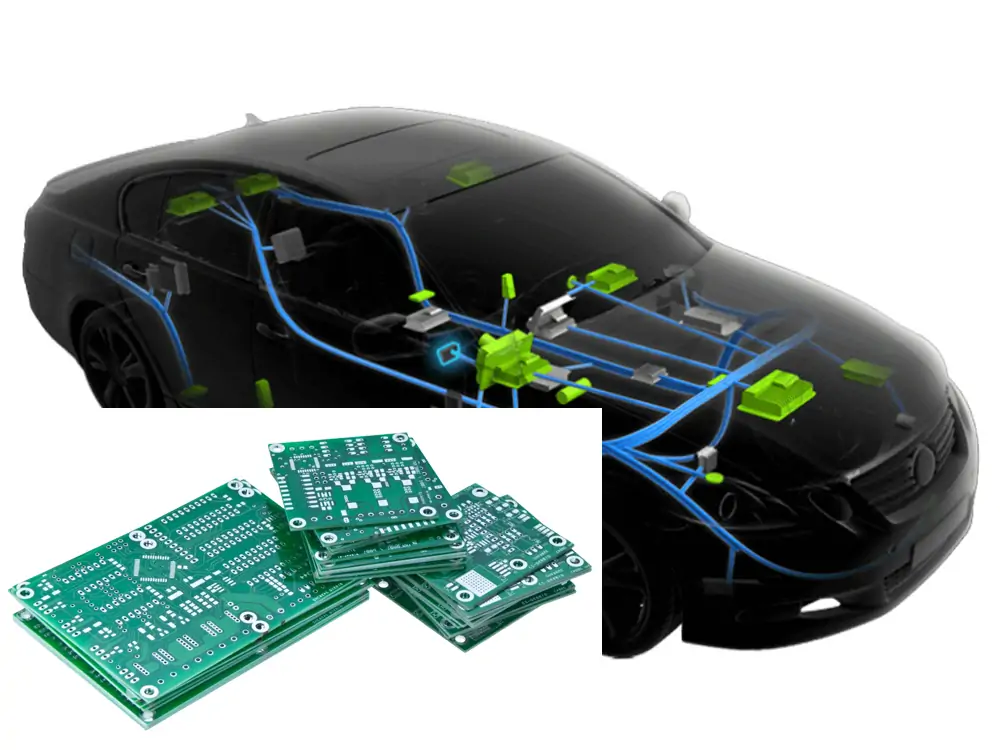

Automotive PCBs are a high-tech product used in the field of automobile manufacturing. These boards are used to control the various systems of the car, including the engine, brakes, electricity, audio, and more.

Applications of Automobile PCBs

- Engine Control Unit (ECU):

- PCB is used in medical diagnostic and testing equipment.

- Engine Control Unit (ECU):

- PCB is used in medical diagnostic and testing equipment.

- Engine Control Unit (ECU):

- PCB is used in medical diagnostic and testing equipment.

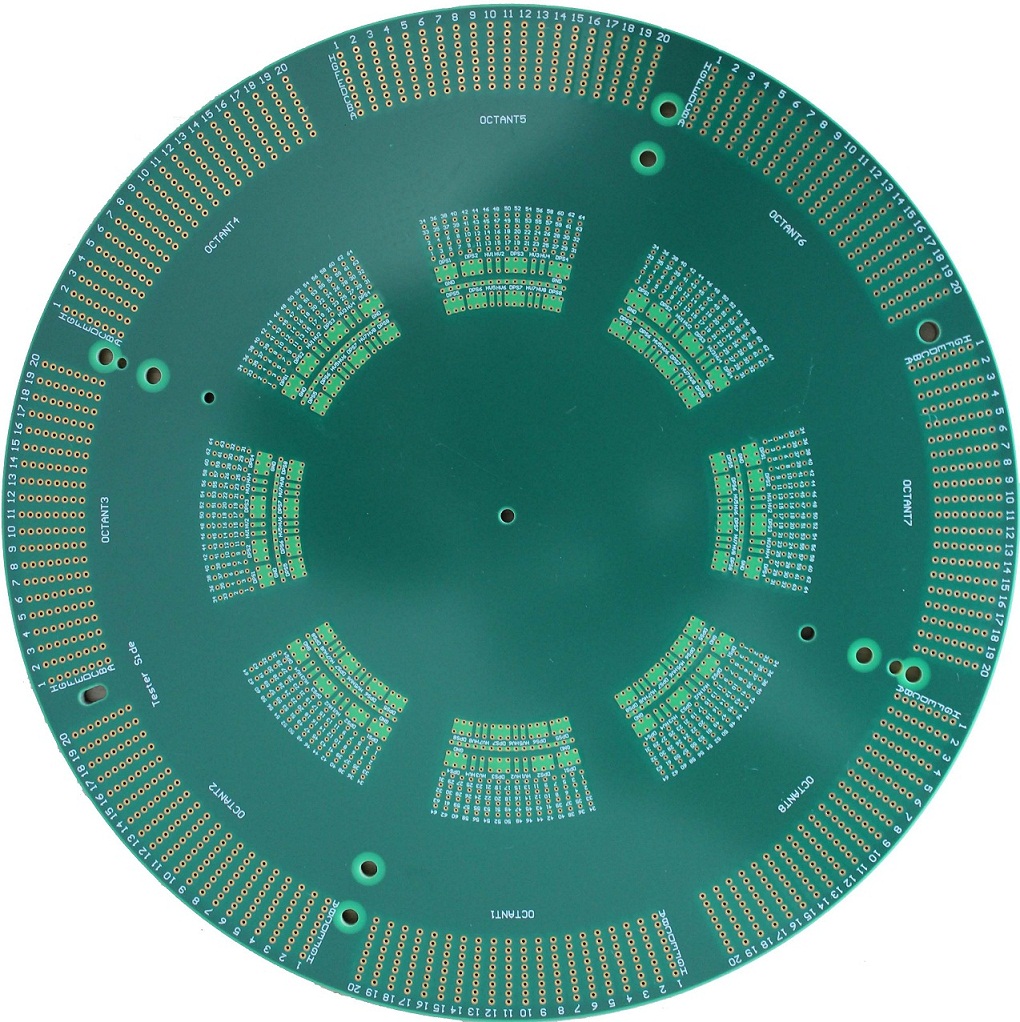

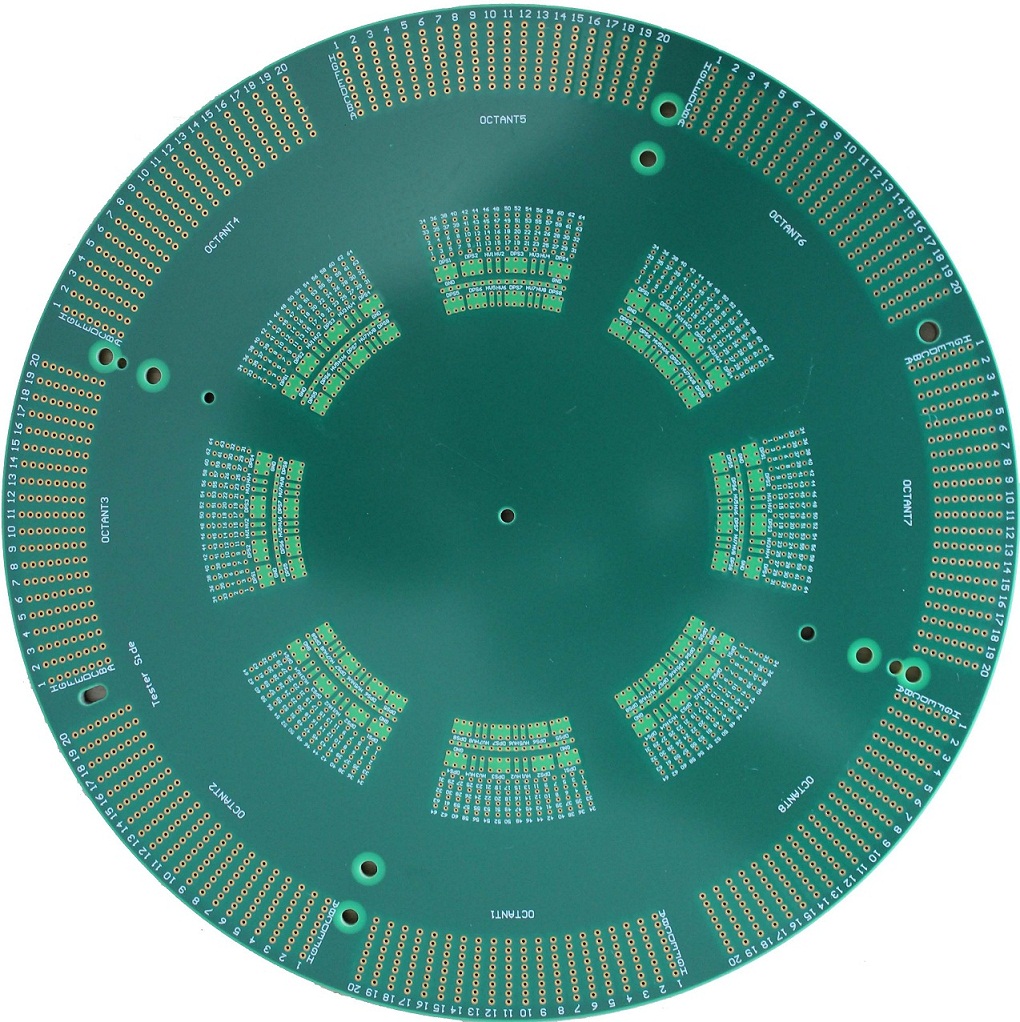

Types of Automotive PCBs

Automotive PCB standards

| standard encdoing | standard name | Publisher | required content |

|---|---|---|---|

| IPC-6012D | Qualification and Performance Specification for Rigid Printed Boards | IPC | Quality and Performance Specifications for Rigid Circuit Boards |

| IPC-6013C | Qualification and Performance Specification for Flexible Printed Boards | IPC | Quality and Performance Specifications for Flexible Circuit Boards |

| IPC-6018B | Qualification and Performance Specification for High Frequency (Microwave) Printed Boards | IPC | Quality and Performance Specifications for High Frequency (Microwave) Circuit Boards |

| IPC-2221B | Generic Standard on Printed Board Design | IPC | Common standards for circuit board design |

| IPC-4101C | Specification for Base Materials for Rigid and Multilayer Printed Boards | IPC | Specifications for Rigid and Multilayer Circuit Board Substrates |

| AEC-Q100 | Failure Mechanism Based Stress Test Qualification for Integrated Circuits | Automotive Electronics Council | Stress testing and quality specification for integrated circuits |

| ISO 26262 | Road Vehicles – Functional Safety | International Organization for Standardization | Functional safety regulations for road vehicles |

It should be noted that different car manufacturers may have their own standards and requirements for automotive circuit boards, so specific requirements may vary.

Why Choosing UETPCB For Medical Device Printed Circuit Board Fabrication

Quality

Quality

Quality

Quality

Quality

Quality

This is heading text

High volume PCB Assembly refers to bulk printed circuit board assembly projects of 10,000 pieces or more, in one cycle of production with DFM and DFT. This is highly popular in high-end modern electronic manufacturing companies.

The benefits of high volume PCB Assembly are

- One-time design and prototyping services

- Faster time-to-market

- cost-efficient as you can purchase in bulk

- Consistent quality

- Production uniformity

- Shortened production cycles

Choosing a high volume PCB manufacturing company is quite a daunting task in this cut-throat competitive space. Two of the most common things one looks for in any company are quality and cost-effectiveness. Besides, you can also look into their experience, manufacturing capabilities, turnaround time, responsiveness, value for time & money, flexibility, and customization options.

Mer-Mar Electronics is a USA-based PCB fabrication and manufacturing company with over 4 decades of experience in PCB assembly services. We are an ISO-certified and ITAR-compliant company. We offer high volume circuit boards in the least turn-around time, flexible shipment plans, and at competitive prices. We follow a client-centric approach to ensure guaranteed quality satisfaction.

You can send your Gerber files and BOM to us We would provide you the quote Give your confirmation and the order We start with PCB fabrication component procurement We perform soldering and testing Finally, we go for packaging and shipping to you.

Well, we can accurately present the time based on the complexity of your board. Let us first go through your Bill of Materials (BOM) and Gerber files. See how much time it takes.

Yes, we do. After the PCB assembly, we can launch an x-ray test on your components. The additional charges will be levied after the assembly test.

We make sure you face zero issues. However, if unfortunately, you face any problems with the boards, please send high-resolution images for proper evaluation. If we get a confirmation of the root cause, we will take responsibility for your board repairs.

As part of the high volume production process, we provide components and parts procurement for optimizing the manufacturing process at zero price. Also, repeat customers may also take advantage of loyalty discounts to reduce the long-term costs of production. Depending on your requirements, we would let you know the final costs.

Yes. We do offer reliable customer support for your orders from start to finish. We will walk you through every step of the process and our PCB experts will also be available all the time.