PCBA Testing

PCBA Testing

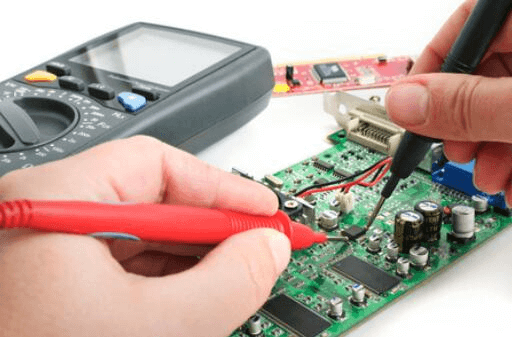

The PCBA testing refers to the electrical conductivity of the printed circuit board mounted with electronic components and the detection based on the input and output values. In the pcba item test, there are numerical relations such as voltage and current between different test points. It is necessary to detect the test points with the help of professional test equipment or a manually operated multimeter, to verify whether the actual PCBA board meets the design requirements. PCBA testing is a key step to ensure the quality of production and delivery. Any PCBA manufacturer should strictly follow the PCBA testing standards and proceed with the test according to the customer’s test plan. Our internal R & D department can customize the PCBA test plan according to the needs of customers. In terms of pcba testing, especially pcb assembly testing and test in circuit, UETPCBA is experienced and professional, which can test the products strictly to provide customers with high-quality PCBA products.

PCBA Testing Principle

PCBA Testing Fixture

PCBA Testing Types

ICT(In-Circuit Test): in-circuit test mainly tests the soldering condition of the components, the on-off of the circuit, the value of voltage and current, the fluctuation curve, the amplitude, and the noise, etc.

FCT(Functional Circuit Test): The test needs to carry out IC programming, simulate the function of the whole PCBA board, find the problems existing in the hardware and software, ensure the performance of PCB manufacturing and soldering. Fct testing pcb is also equipped with necessary production fixtures and test racks.

Burn In Test: Long-time and periodic simulation of user input/output is carried out on PCBA boards that have been programmed and passed FCT to test their durability and soldering reliability. Check whether the pcba circuit board is powered on and whether it is faulty. Under special circumstances, the PCBA board needs to be exposed to a specific temperature and humidity environment.

Fatigue Test: This is mainly to sample test the PCBA board, and perform high frequency and long-time operation of the function, observe whether there is a failure, test the probability of failure, to feedback the performance of PCBA board in electronic products.

The importance of PCBA testing

PCB assembly and fabrication services for various industries

one-stop supplier!

This is heading text

High volume PCB Assembly refers to bulk printed circuit board assembly projects of 10,000 pieces or more, in one cycle of production with DFM and DFT. This is highly popular in high-end modern electronic manufacturing companies.

The benefits of high volume PCB Assembly are

- One-time design and prototyping services

- Faster time-to-market

- cost-efficient as you can purchase in bulk

- Consistent quality

- Production uniformity

- Shortened production cycles

Choosing a high volume PCB manufacturing company is quite a daunting task in this cut-throat competitive space. Two of the most common things one looks for in any company are quality and cost-effectiveness. Besides, you can also look into their experience, manufacturing capabilities, turnaround time, responsiveness, value for time & money, flexibility, and customization options.

Mer-Mar Electronics is a USA-based PCB fabrication and manufacturing company with over 4 decades of experience in PCB assembly services. We are an ISO-certified and ITAR-compliant company. We offer high volume circuit boards in the least turn-around time, flexible shipment plans, and at competitive prices. We follow a client-centric approach to ensure guaranteed quality satisfaction.

You can send your Gerber files and BOM to us We would provide you the quote Give your confirmation and the order We start with PCB fabrication component procurement We perform soldering and testing Finally, we go for packaging and shipping to you.

Well, we can accurately present the time based on the complexity of your board. Let us first go through your Bill of Materials (BOM) and Gerber files. See how much time it takes.

Yes, we do. After the PCB assembly, we can launch an x-ray test on your components. The additional charges will be levied after the assembly test.

We make sure you face zero issues. However, if unfortunately, you face any problems with the boards, please send high-resolution images for proper evaluation. If we get a confirmation of the root cause, we will take responsibility for your board repairs.

As part of the high volume production process, we provide components and parts procurement for optimizing the manufacturing process at zero price. Also, repeat customers may also take advantage of loyalty discounts to reduce the long-term costs of production. Depending on your requirements, we would let you know the final costs.

Yes. We do offer reliable customer support for your orders from start to finish. We will walk you through every step of the process and our PCB experts will also be available all the time.