Through-Hole PCB Assembly

Through-Hole PCB Assembly

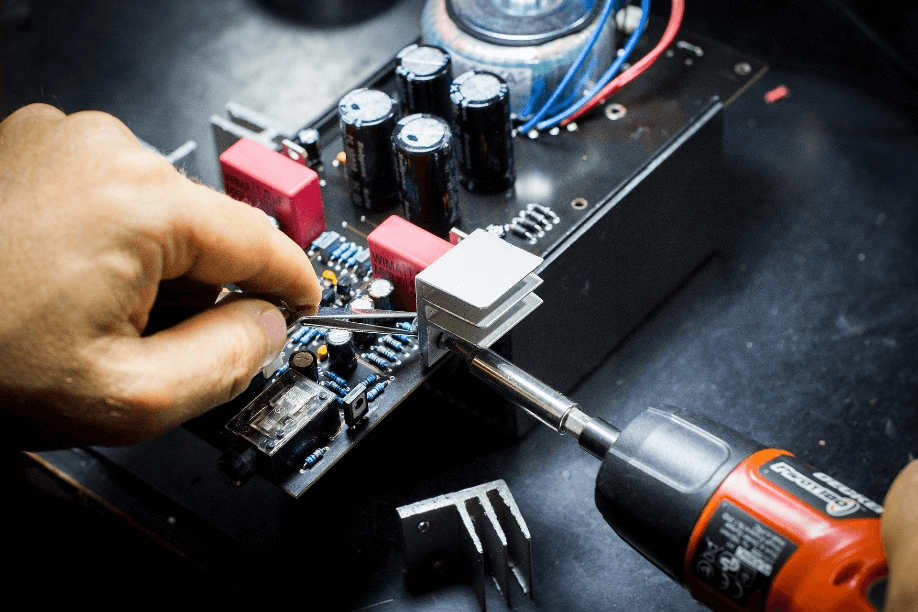

The Through-Hole Technology PCB Assembly Service provided by Kingda helps customers to complete the placement of plug-in components on PCB circuit boards, to ensure the reliability and quality stability of soldering. The plug-in process strictly follows the SOP operation guidelines, arranges workstations according to the classification of materials, and conducts targeted staff training. During the whole through-hole PCB assembly process, the related engineers and quality personnel will patrol the whole process and guide to ensure the quality.

Our through-hole PCB Assembly services comprise both manual for complex through-hole assembly or simple samples and automated techniques when it comes to small-volume production. As a through-hole pcb assembly manufacturer, Kingda is fully capable to provide cost-effectively prototype, small quantity and mass production runs, SMT assembly, and through-hole pcb assembly manufacturing.

This is heading text

- Manual and automated Insertion

- Lead-free or RoHS soldering

- Double Wave Flow Solder

- Selective wave soldering

- Use low and high melting point solder

- Conformal Coating

- IC Programming

- Inspection and functional testing

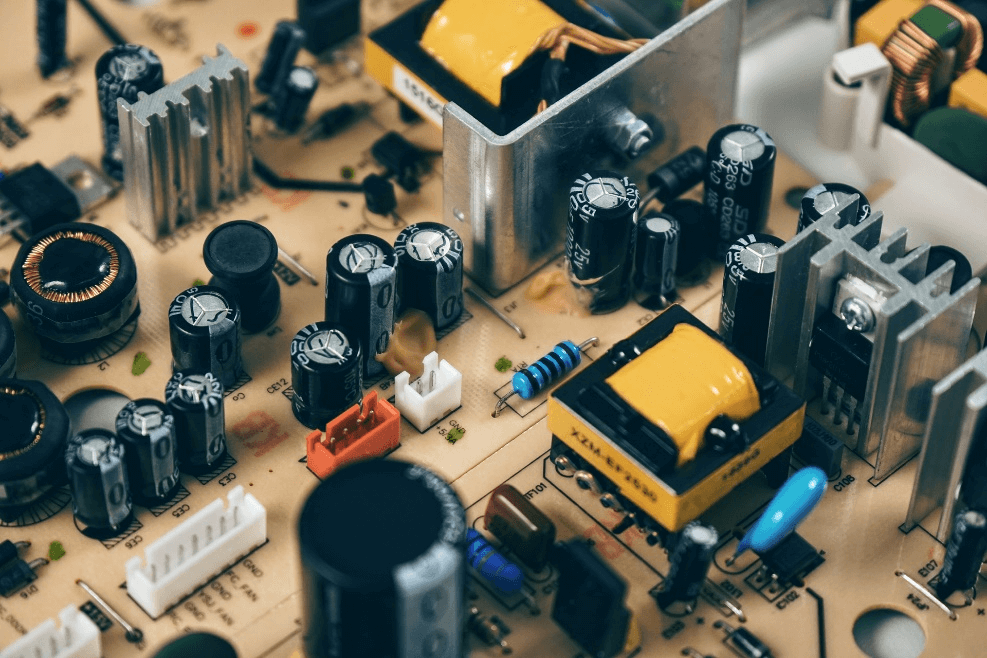

Our Through-hole Assembly Equipment

- Through-hole Assembly x 4 lines

- Plug-in AOI: Check the components and solder joints for defects

- Automated wave soldering X 2 lines

- Manual plug-in insertion X 40 workstations

- Testing X 4 lines

- PCBA aqueous washing machine x 2 sets

- In-house conformal coating and programming device

Advantages of Through-hole PCB Assembly

Easy Prototyping: Through-hole technology PCB assembly enables faster prototyping than SMT PCB assembly, and through-hole components can be easily replaced. In addition, you can evaluate the board design even before the board is made.

High Power Capability: Through-hole assembly can easily meet high power requirements. The through-hole components operate in conjunction with the printed circuit board, they can easily withstand mechanical and environmental pressures. This is why through-hole components are widely used in aerospace and military electronics that need to withstand high temperatures, high voltage and high current.

Component Durability: The through-hole installation is known to help create a strong physical bond between components, components are soldered securely to the sides of the circuit board, helping to improve its durability.

High Reliability: Through-hole PCBs and components are best suited for highly reliable products that require stronger connections between layers

Through-hole PCB Assembly is a part of PCBA electronic processing, manual work is relatively more, put forward higher requirements for management. By implementing a complete set of the quality management system (ISO9001:2015, ISO13485, IATF16949) and equipped with continuous improvement of automation equipment, our Through-hole PCB Assembly service consistency, and reliability, winning customer praise.