Turnkey PCB Assembly

Turnkey PCB Assembly

We are a professional PCB fabrication and assembly company. Our PCB assembly services include PCB procuring components, assembly, testing, delivery, and aftermarket. We also have warranty support and advanced PCB assembly turnkey service.

All our design, prototyping, and assembly processes adhere to the regulations laid in IPC-A-610 Class 2 and Class 3.

Our PCB Assembly Capabilities

PCB Fabrication

Multi-layer

Heavy Copper

Custom+

PCB Assembly

BGA Assembly

Through-Hole Assembly

Mixed Assembly

Solder Types

Lead-free

RoHS Compliant

No-clean and Water Clean Fluxes

Parts Management

Ball Grid Array (BGA)

QFN and QFP

Small Chip Package (Pitch of 0.2 mm)

Engineering Support

Assembly with expert opinions

BOM verification.

Complete Design for Assembly (DFA) review

Additional Capabilities

Conformal coating service

Custom Packaging and Labeling

Cable and Wire-harness assembly

AOI (Automated Optical Inspection): This testing checks for missing components. It also identifies any missing solder paste or polarity.

X-ray: This testing is commonly performed on Quad-flat No-lead (QFN) PCBs and Ball Grid Arrays (BGAs).

ICT (In-Circuit Test): In-circuit testing will check whether a circuit has any shorts or opens. It also ensures that the turnkey PCB assembly is done correctly by checking carious electrical factors. These factors often include resistance, capacitance, and other quantities.

Visual inspection: This involves a general quality check of the circuit board.

FAI (First Article Inspection): checking the first sample soldering before the production run.

Functional testing: This process checks the functionality of the PCB. It also ensures that the performance is according to the expectations.

Reliability Testing:Reliability testing is an essential part of PCBA product development. Vibration and temperature simulation tests are available in our laboratory.

This is heading text

- Requirements Analysis

- Quotation and Agreement

- Component Procurement

- Stencil Manufacturing

- PCB Fabrication

- Pick and Place

- Reflow Soldering

- 8. Through-Hole Assembly

- 9. Inspection

- 10. Testing

- 11. Cleaning

- 12. Final Inspection

- 13. Packaging and Shipping

Types Of Our PCB Assembly Services

Prototype assembly

We excel in the rapid production of prototype and low-volume printed circuit board assemblies, offering both consignment and turnkey solutions.

Production and assembly

Our high-speed automated machines are equipped to manage production orders without any Non-Recurring Engineering (NRE) fees, minimum order requirements, or contractual obligations.

Box build

We provide services for box build and electro-mechanical assembly.

Consigned Assembly (kitted)

You provide all electronic components and the bare printed circuit boards, while we employ cutting-edge automated equipment to assemble your boards.

Partially Consigned

You provide some components that you have in inventory, including the “hard-to-find” and “custom” parts. We source the remaining parts and fabricate the PCBs, which are then assembled here.

Turn key Assembly

We oversee the complete process, from acquiring bare printed circuit boards and all necessary components to assembly and testing.

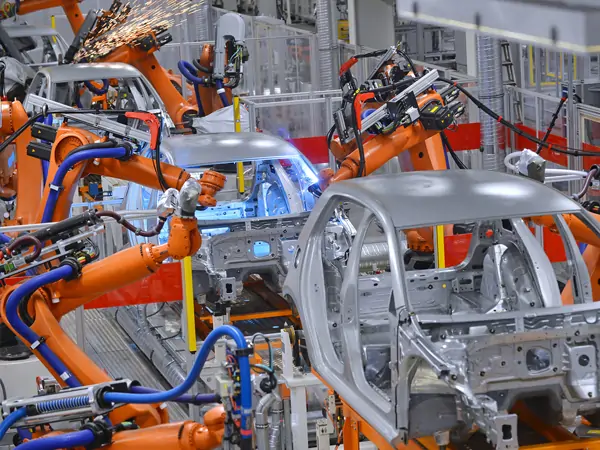

Applications

Why choose Kingda as Partner for Full Turnkey PCB Assembly Services?

Faster Quotes

Our full turnkey PCB assembly service offers 24-hour quotes for your China PCB turnkey assembly order.

Shorter Lead Time

We offer complete turnkey PCB assembly services, ensuring efficient and rapid electronic assembly. We excel in PCB fabrication, component sourcing, and assembly. So, cooperate with us for quick and efficient prototype PCB manufacturing.

Lower CostLower Cost

We specialize in China turnkey PCB assembly. We produce reliable products and offer long-term cooperation with the distributors and buyers. In addition, we are one of the dominating China PCB turnkey assembly manufacturers. You can get significant cost savings with our end-to-end solutions.

Better quality control

UETPCB is a dependable PCB fabrication and China PCB turnkey assembly manufacturer. We prioritize quality through rigorous control measures. We aim to deliver advanced customer service.