Wire Harness Assembly

Wire Harness Assembly

We are always trying to satisfy all customers’ demands for their products.

Our priority includes working with each specification to allow great product performance. Our goal is to ensure that our product can achieve top results.

Wire Harness Industries

Our inventory is vastly full of simple hand tools and semi-automatic equipment. These products are designed to meet all your required specifications.

◆Motor cables

◆Servo cables

◆Power Cables

◆Signal cables

◆Sensor cables

◆C-Tracks cables

◆D-Subminiature

◆R-F Assemblies

◆Data Link Assemblies

◆Potting applications

◆Aerospace

◆Automotive

◆Cameras and Lighting

◆Fire Fighting Equipment

◆Laser Technology

◆Machine Control

◆Medical

◆Military

◆Robotics

◆Telecommunication

Wire Harness Capabilities

Kingda keeps advanced harness manufacturing and cable harness assembly technology. As a result, we have become a reliable Chinese harness and cable assembly manufacturer worldwide. We provide a wide range of assembly services. Among these, the custom wire harness service is noteworthy. You can get professional suggestions from your original idea to the final product.

Kingda has cable and wire harness assemblies manufacturing and support services for customers. In addition, we also offer industrial, electromechanical, power supply, and custom harness services.

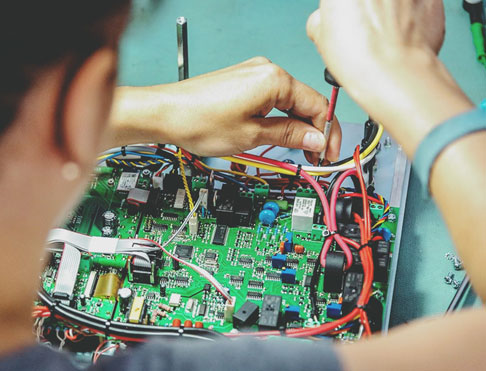

We are a professional Chinese wire harness manufacturer. Our automated wire capability includes cutting, stripping, terminating, splicing, and soldering. We can deal with cable and wires ranging from 24 AWG to 4/0 AWG. Besides, our service scope includes all sizes of single wires and complex wire harness assemblies.

Wire Harness Assembly Process

Wiring assembly processes include but are not limited to the following:

Installing the wires and/or subassemblies on the assembly board.

Routing wires and/or subassemblies through any required sleeves.

Applying wraps, ties, or tapes, particularly on any branch-outs.

Crimping terminals onto wires, especially if more than one wire goes into one terminal.

Wire Harness Testing

Kingda is a responsible and professional Chinese cable harness manufacturer. We always focus on the quality of the harness manufacturing process and wire harness assembly boards. In this case, we use a test board to test a cable or wire harness’s electrical functionality. The test board can be pre-programmed according to the required electrical characteristics. It can also be tested individually or in multiple numbers of the completed harness by plugging it into the test board.

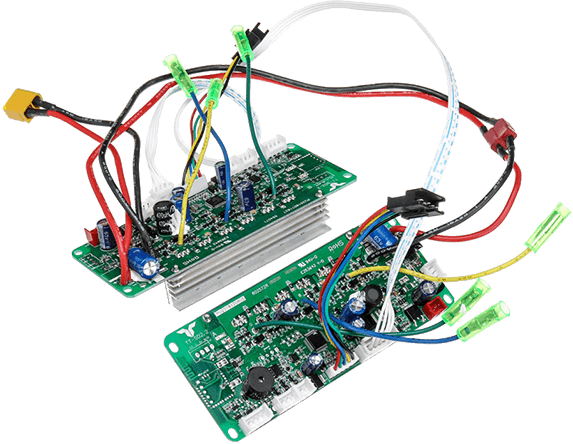

PCB assembly and fabrication services for various industries

one-stop supplier!

This is heading text

High volume PCB Assembly refers to bulk printed circuit board assembly projects of 10,000 pieces or more, in one cycle of production with DFM and DFT. This is highly popular in high-end modern electronic manufacturing companies.

The benefits of high volume PCB Assembly are

- One-time design and prototyping services

- Faster time-to-market

- cost-efficient as you can purchase in bulk

- Consistent quality

- Production uniformity

- Shortened production cycles

Choosing a high volume PCB manufacturing company is quite a daunting task in this cut-throat competitive space. Two of the most common things one looks for in any company are quality and cost-effectiveness. Besides, you can also look into their experience, manufacturing capabilities, turnaround time, responsiveness, value for time & money, flexibility, and customization options.

GOPCBA is a USA-based PCB fabrication and manufacturing company with over 4 decades of experience in PCB assembly services. We are an ISO-certified and ITAR-compliant company. We offer high volume circuit boards in the least turn-around time, flexible shipment plans, and at competitive prices. We follow a client-centric approach to ensure guaranteed quality satisfaction.

You can send your Gerber files and BOM to us We would provide you the quote Give your confirmation and the order We start with PCB fabrication component procurement We perform soldering and testing Finally, we go for packaging and shipping to you.

Well, we can accurately present the time based on the complexity of your board. Let us first go through your Bill of Materials (BOM) and Gerber files. See how much time it takes.

Yes, we do. After the PCB assembly, we can launch an x-ray test on your components. The additional charges will be levied after the assembly test.

We make sure you face zero issues. However, if unfortunately, you face any problems with the boards, please send high-resolution images for proper evaluation. If we get a confirmation of the root cause, we will take responsibility for your board repairs.

As part of the high volume production process, we provide components and parts procurement for optimizing the manufacturing process at zero price. Also, repeat customers may also take advantage of loyalty discounts to reduce the long-term costs of production. Depending on your requirements, we would let you know the final costs.

Yes. We do offer reliable customer support for your orders from start to finish. We will walk you through every step of the process and our PCB experts will also be available all the time.